Material, also called item/part/product in other domains and solutions, is THE most important master data object as it is central to many mission-critical business processes in sales, commerce, design, manufacturing, logistics, customer service and maintenance. The creation of material is an extremely cross-functional exercise that spans the whole supply chain. What starts off as a vision and a sketch on a napkin turns into a finished product. Like the Cybertruck below.

Coming back to the topic of Materials Master Data Management. We have seen a very unfortunate pattern of data entry oriented master data management tools (MDM) trying to tackle Materials Master Data Management and failing miserably. Right off the bat we would like to establish the following

Materials master data is not something you type into a form or an Excel sheet, run some validations, and send it via an approval workflow, and call it a day. Materials master data is the outcome of analysis and decision-making by Design, Manufacturing, Purchasing, Logistics, Marketing and Sales/Customer Service stakeholders.

Facets of Material Master Data

Regardless of what some vendors advocate and would like you to believe, MDM most definitely is not the following

Design/Engineering Related Master Data

More often than not Design and Engineering functions are the starting point of the process when creating new parts/materials. While not strictly treated as master data by ERP systems, key engineering information such as Drawings, Visualization files, etc. should considered as Master Data related to Materials.

Drawings and Visualization Data

Drawings contain key dimensional and specification information that is often used by manufacturing and suppliers for properly following instructions (design, manufacturing, tooling) as well as quoting.

Bill(s) of Material

Bill of Material is element of Material Master Data. In most cases Bills of Material originate in design/engineering systems (MCAD/ECAD) and needs to be transferred to ERP/MRP/Supply Chain Planning systems so that MRP runs, purchasing and manufacturing planning can be effectively supported.

Alternates

Alternate materials/parts are an important master data element. These alternate parts are used whenever for some reason (usually shortages) a plant is not able to use the primary part for manufacturing/assembly.

Purchasing related information is key master data for materials that are purchased. Purchasing related information can include

Approved Suppliers

Key master data related to purchasing is approved suppliers for the materials. The related information can include manufacturer and manufacturer part information as well as cost and lead time information.

Approved Manufacturer Parts

Approved manufacturers and approved manufacturer parts are critical master data information, especially when working with electronics and semiconductor components.

Cost and Ordering Related Information

In addition, cost (agreed price), quantity discounts, minimum and standard order quantities, packaging units, order lead times are key master data related to purchasing.

Material Master Data for Lean Operations – Plan for Every Part

Plan for every part (PFEP) is the blueprint for effectively managing logistics and manufacturing aspects of a part (for Finished Goods as well as Raw Materials/Purchased Components). A “Plan For Every Part” is a plan to make sure

Right part is available where needed at the right time in the right quantity

More about Master Data related to Plan for Every Part

Master Data for Sales and Marketing

One of the best ways to understand master data for sales and marketing is to review master data needs for E-commerce. More on master data for E-commerce.

SAP Material Master

Many companies use SAP ERP as the primary system for Finance, Sales and Distribution, Purchasing, Production Planning, MRP, Maintenance and other business processes. SAP Material Master plays an outsized role on how well business processes are designed and implemented for the companies that use SAP. We created an entirely different post for delving deep into SAP Material Master – Anatomy of SAP Material Master.

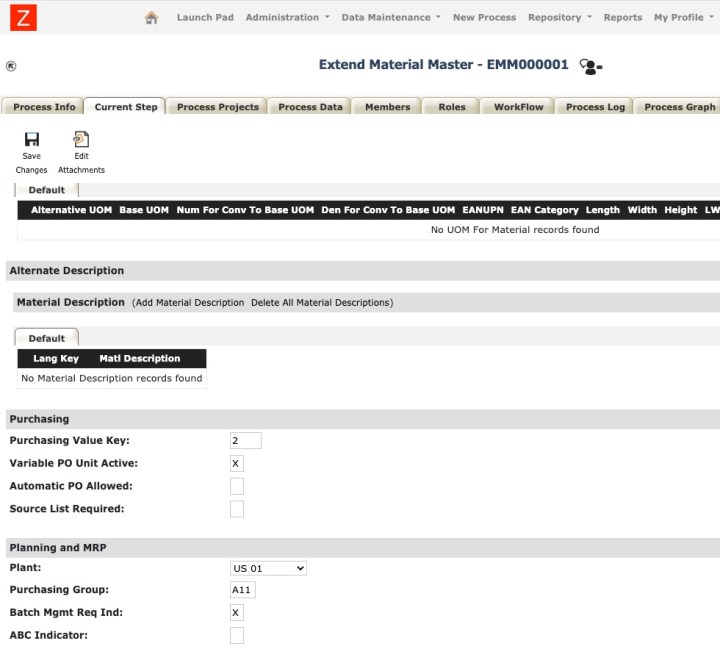

Material Master Data Workflows in the Real World

New Material Creation

If you ask a design engineer, product engineer or material management stakeholder they will actually say that creating new materials might look something like below (for illustration only)

Changing Materials

And changing materials might look something like below. And typically an Engineering Change Request and/or Change Order is used to change materials.

Adding/Changing Bill of Materials (BOM)

Bill of Material (BOM) is a key aspect of material master data. New BOMs and changes to existing BOMs are actually related to new material creation or changes to existing materials. Any MDM solution that cannot handle BOMs will not be an effective MDM solution for Materials.

A BOM change is a change to Material

Collecting Right Information from the Right Person

Since many people are involved in creating material master data it is best to get the right information from the right person. For example, a design engineer is in the best position to provide information related to “Weight” for example. On the other hand purchasing and manufacturing stakeholders are better able to obtain lead time and lot sizing information.

Validation at the Right Time, and By the Right Person

It is still a good idea to add validations (required fields, ranges, etc.) for materials master data. But there is a right time for validation. Too much validation right in the beginning can frustrate users and users that have no idea will select incorrect information or may just give up. Validation at later stages of the master data process can make sure that accurate master data makes it into downstream systems.

Summary

Materials Master Data Management is one of the most cross-functional process in the organization and the extended supply chain and is connected to many upstream and downstream processes in design/engineering, sales, marketing, purchasing, manufacturing and logistics. Treating it as a cross-functional business process leads to many advantages and benefits to individuals, teams and organizations.